Supply OEM/ODM China Air Source High Temp Large Capacity Heat Pump for Hot Water Project

“Based on domestic market and expand overseas business” is our improvement strategy for Supply OEM/ODM China Air Source High Temp Large Capacity Heat Pump for Hot Water Project, In addition, we would properly guide the customers about the application techniques to adopt our products and the way to select appropriate materials.

“Based on domestic market and expand overseas business” is our improvement strategy for Air To Water Heat Pump, China Air Heatpump, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

| Specification | ||||||||||||||

| Model | NERS- | B/1.5Y | B/2Y | B/2.5Y | B/3Y | B/5Y | B/6Y | G/8Y | G/10Y | G/12Y | G/24Y | G/30Y | G/40Y | |

| Rated heating capicity | KW | 6.5 | 9 | 10.5 | 12.8 | 22.5 | 26.2 | 34.5 | 45 | 53.2 | 101 | 120 | 150 | |

| Cooling capicity | KW | 4.55 | 6.3 | 7.35 | 8.96 | 15.7 | 18.3 | 23.5 | 30 | 37.2 | 74.2 | 91 | 106.8 | |

| Input power | KW | 1.2 | 1.67 | 1.95 | 2.43 | 4.24 | 5.12 | 6.65 | 8.65 | 10.2 | 19.6 | 23.5 | 29.1 | |

| Power source | V/Hz | 220V-240V 50Hz / 1phase | 380V-400V / 50HZ / 3phase | |||||||||||

| Rated output water temperature | °C | Rated temperature : 26℃~28℃ , Max temperature : 40℃ | ||||||||||||

| Water flow | m3/h | 2.5m | 3.4 | 4.3 | 5 | 8.7 | 13 | 14.8 | 17.5 | 20.8 | 40 | 52.5 | 68.8 | |

| Refrigeration | R410A | |||||||||||||

| Control mode | Microcomputer central processor (line control) | |||||||||||||

| Compressor | Form | Rotate type | Scroll type | |||||||||||

| Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 4 | ||

| Brand | Mitsubishi | Copeland | ||||||||||||

| Unit | Net size | mm | 894*402*538 | 942*372*548 | 1010*401*622 | 1108*518*904 | 1108*489*1257 | 1108x489x1257 | 1360*854*1320 | 1360*854*1320 | 1360*854*1320 | 2180*1000*1980 | 2180*1000*1980 | 2180*1803*1760 |

| Net weight | Kg | 60 | 65 | 80 | 100 | 155 | 165 | 260 | 300 | 320 | 750 | 800 | 1258 | |

| Nosie level | dB(A) | ≤48 | ≤48 | ≤48 | ≤50 | ≤55 | ≤58 | ≤60 | ≤60 | ≤60 | ≤64.8 | ≤66 | ≤68 | |

| Fan | Form | internal rotor motor, plastic leaves | internal rotor motor | |||||||||||

| Ambient temperature | °C | (-10℃ – 50℃) | ||||||||||||

| Inlet pipe diameter | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 3″ | 3″ | 3″ | ||

| Outlet pipe diameter | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 1.5″ | 3″ | 3″ | 3″ | ||

| Testing conditions: Heating :DB/WB: 24°C/19°C , Water In/Out: 26 °C / 28°C Cooling :DB/WB: 35°C/32°C , Water In/Out: 30 °C / 28°C |

||||||||||||||

product Advantage

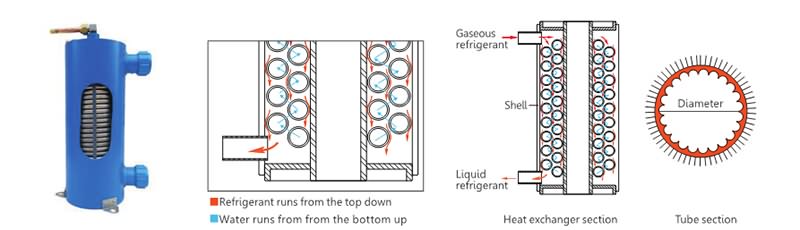

1.Patented Efficient Heat Exchanger

The patented high efficiency heat exchangers have a strong counter current design and are helpful for refrigerant super cooling between the shell and tubes s small this leads to a larger flow which makes return easy Addition the Large tube diameter prevents tubes from deposits and blocking

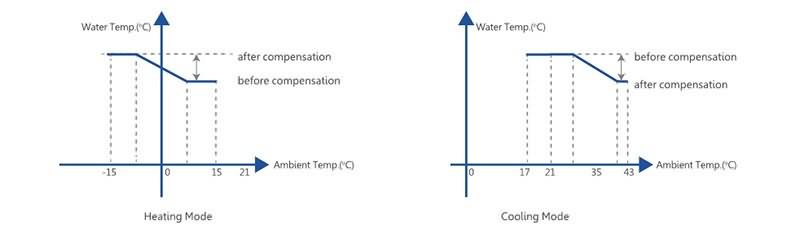

2.Temperature Compensation Technology

Automatic compensation technology Can adjust water temperature according to the ambient temperature which means you always feel comfortable ,Whether in winter or summer.

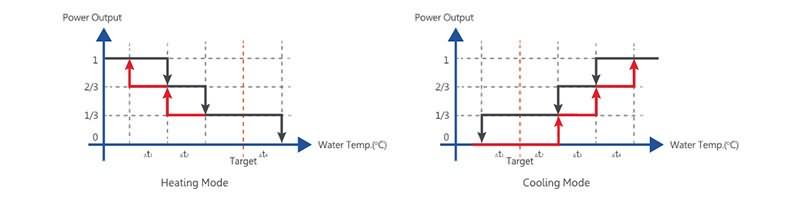

3.Compressor Interchange Control Logic

Compressor interchange control logic ensures only the energy required delivered to the terminals with up to three compressors on or of which provides you both comfortable temperatures and a longer service life of the units while consuming less energy

Detailed Features

- 1.The world famous EEV electronic expansion valve is critical PID control the volume of the refrigerant accurately and reduce energy consumption.

-

2.The compressor can be on or off according to the actual energy need so the units are reliable and easy tp control.

-

3.Air exchanger(fins-coil)with hydrophilic coating has stronger anti-corrosion feature and performs higher efficiency.

-

4.With strong – countercurrent design,the patented C&S heat exchanger is conductive to improving the Efficiency and reliability of the unit.

Packing&Delivery

Relatice products

B1.5Y B2Y

B3Y

Products categories

-

Phone

-

E-mail